YT510 Aramidine insulation paper

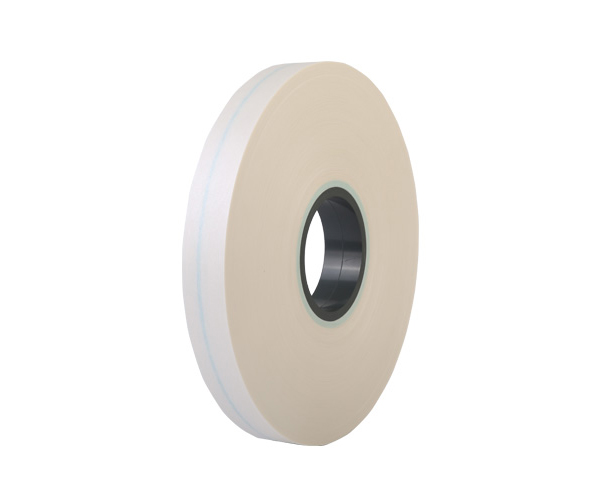

1. The product is a milky white flat paper roll shape. The paper structure is dense and the texture is uniform.

2. The paper surface is flat, smooth, without pores, no hair, no hair, and neat edges.

3. With excellent thermal stability and flame retardability, it can be used normally at high temperatures at 210 ° C for a long time (above H level).

4. High mechanical performance, high stretching strength and tearing strength.

5. It has good compatibility with various types of commercial paint, lubricant, etc.

6. Safe, environmental protection, chemical resistance, and pass certification such as SGS Rohs and Reach.

7. Has excellent electrical insulation performance, high degree of dielectric strength, and low dielectric loss.

Inquire Now

YT510 Bitchida insulation paper is a sinking fiber that is made of high -mechanical strength short -cut fiber and the strength of the dielectric and adhesive strength with high mechanical strength. The interval thermal insulation paper is a pure intercate polyfrinamide component.

2. Performance use

1. It has excellent high temperature resistance and flame retardant characteristics. UL94VTM-0 and V-0, UL746B RTI-210 ℃ security recognition. It does not melt and ignite in the air; it can also ensure that the performance is stable for 10 years at the environmental temperature of 210 ° C.

2. Excellent chemical stability and compatibility. It is basically not affected by most solvents and is resistant to acid and alkali. It can be compatible with all kinds of varnish, adhesive, transformer oil, lubricant and frozen agent;

3. The structure is dense, the surface is smooth, and has high mechanical strength, flexibility and reflection;

4. Has a high degree of dielectric strength, lower dielectric constant and medium loss. The low dielectric constant can make the electric field distribution between insulation and cold but medium.

5. Have good moisture tolerance. The strength of the dielectric under high humidity conditions will be slightly lower than that of dry conditions, and many mechanical energy will improve.

6. Non -toxic environmental protection and safety, comply with relevant regulations of ROHS and Reach, can effectively reduce the impact on people and the environment;

7. For occasions that are used in almost all known electrical insulation, it can run in the short -term overload, strong anti -load ability, and good high temperature resistance;

8. There are 9 thick specifications from 0.05mm to 0.76mm from 0.05mm to 0.76mm.

Typical performance indicators

Standard thickness | mi l | 2 | 3 | 5 | 7 | 10 | 12 | 15 | 20 | 30 |

test method |

mm | 0.05 | 0.08 | 0.13 | 0.18 | 0.25 | 0.3 | 0.38 | 0.51 | 0.76 | ||

Typical thickness | mm | 0.055 | 0.078 | 0.13 | 0.18 | 0.245 | 0.290 | 0.365 | 0.515 | 0.755 | GB /T 451.3-2002 |

pivot weight | g /m | 41 | 63 | 116 | 172 | 249 | 300 | 385 | 525 | 675 | GB /T 451.2-2002 |

density | g /cc | 0.74 | 0.80 | 0.90 | 0.95 | 1.01 | 1.03 | 1.05 | 1.02 | 0.89 | |

tensile strength N /cm | MD | 39 | 66 | 140 | 220 | 255 | 320 | 380 | 500 | 630 |

GB /T 12914-2008 |

CD | 15 | 29 | 56 | 105 | 165 | 200 | 260 | 345 | 380 | ||

elongation % | MD | 7.0 | 8.5 | 10.0 | 11.0 | 13.5 | 16 | 13 | 13 | 13 | |

CD | 6.5 | 9.0 | 11.5 | 12.5 | 14.5 | 15.5 | 12 | 13 | 11 | ||

Rift degree 1)

N | MD | 0.65 | 1.00 | 2.00 | 3.50 | 5.00 | 6.50 | 10.00 | 13 | / |

GB /T 455-2002 |

CD | 1.15 | 1.70 | 3.30 | 4.80 | 6.00 | 8.00 | 13.50 | 16 | / | ||

Dielectric power Degree 2) |

kv /mm |

15 |

16 |

15 |

16 |

19 |

21 |

19 |

13.5 |

12 |

GB /T 1408.1-2006 |

Dielectric often Number 3) |

1.5 |

1.5 |

2.1 |

2.4 |

2.5 |

2.7 |

3.0 |

3.1 |

3.2 |

GB /T 1409-2006 | |

insertion loss factor 3) |

× 10-3 |

4 |

5 |

6 |

7 |

8 |

8 |

8 |

8 |

8 | |

300℃ shrinkage% | MD | 3.5 | 3.5 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

GB /T 20629.2-2013 |

CD | 3.0 | 3.0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.0 | 2.0 |

1) Elmenfu tear degree 2) AC fast boost method, upper electrode 25mm, lower electrode 75mm 3) test frequency 50 HZ, make the instrument Xilin bridge, electrode 50mm

MD longitudinal, CD transverse

Please note that the data in the data sheet are typical value, can not be used as a technical specification, unless otherwise stated, all data are measured under "standard conditions" (temperature 23℃, relative humidity is 50% RH), like other papermaking technology products, aramid paper in longitudinal and transverse mechanical performance index of some differences, in some applications can be adjusting the direction of the paper, the use of the paper has to the best performance.

Product size, specifications and packaging

thickness | Typical heavy | breadth | reference length | Refer to volume weight | Refer to the coil diameter | |

mm | mi l | g/㎡ | mm | m | ㎏ | mm |

0.05 | 2 | 41 | 965 | 1250 | 50 | 300 |

0.08 | 3 | 63 | 965 | 900 | 54 | 300 |

0.13 | 5 | 116 | 965 | 540 | 60 | 300 |

0.18 | 7 | 172 | 965 | 390 | 64 | 300 |

0.25 | 10 | 249 | 965 | 260 | 62 | 300 |

0.30 | 12 | 300 | 965 | 200 | 60 | 300 |

0.38 | 15 | 385 | 965 | 170 | 63 | 300 |

0.51 | 20 | 525 | 965 | 130 | 64 | 300 |

0.76 | 30 | 675 | 965 | 90 | 60 | 300 |

Standard width: 965mm ± 7mm

The above width and length are conventional sizes, and can also be divided into large coil products according to customer needs.

(In addition: with 0.05mm-0.25mm thickness, the disk of the product can be divided into a width of more than 8mm, and the product with 0.3mm-0.76mm thickness can be divided into a width of more than 20mm, with a diameter of about 300mm.)

2, internal packaging: plastic film, paper tube, corrugated board sealing head, plug;

3. Outer packaging: corrugated boxes, with product sales labels and UL and RoHS labels;

4. Transportation and packaging: for conventional width paper roll, carton packaging, placed on the wooden tray, fixed with packaging belt, and stretch the film winding.

5. Preservation method: indoor sealed storage, strictly prohibited stacking in the open air, long time damp and direct sunlight.