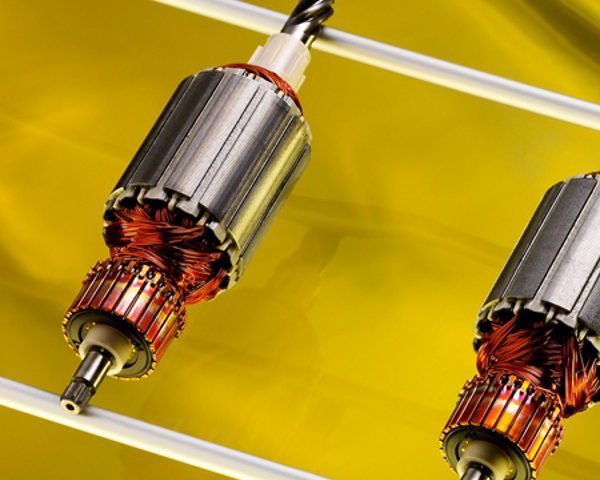

Voltatex® Immersion paint 4200

Chemical composition: low volatile unsaturated polyester amine resin

Product Description:

Voltatex® 4200 series products are a low volatile immersion resin.

VOLTATEX® 4200 conforms to the following EU instructions:

-2003/11/EU (Polytin Penzide)

-2006/121/EU (Reach instruction)

-2011/65/EU (ROHS instruction)

characteristic

• Single component

• excluding styrene and ethylene toluene

• Low volatile

• Refrigerator

• The minimum human contact in the work area

• It is easy to burn the explosion and danger

• It belongs to non -dangerous products in the provisions of transportation regulations

Inquire Now

Resin characteristics after curing:

• Excellent thermal performance and mechanical strength, especially for long -term stress

• Good solvent -resistant steam characteristics

• Outstanding adhesion

mix

Voltatex® 4200 can be used without adding additional catalysts and curing agents.

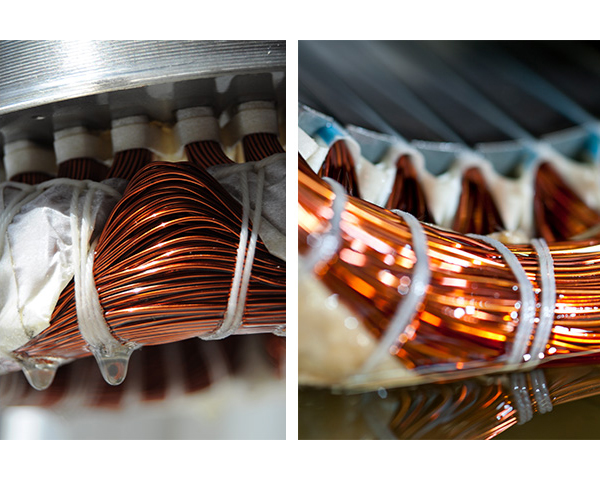

Use process

The impregnated resin can be used for the following process:

• All conventional immersion and decorative process

• Continuous vacuum painting process

• vacuum pressure soaking lacquer process

When the storage is below 25 ° C, if at least 20%of the paint in the monthly paint tank is used and adds new resin, it can grow

Period stable use

Solidify

Voltatex® 4200 is a low volatile resin, but in order to minimize the losses of resin monomers during the curing process, it should be in the shortest time

The impregnation workpiece is warmed to the curing temperature. In addition, within the scope of safety permission, the lowest airflow should be maintained during the cured process

move.

Equipment cleaning

Voltatex® 4200 is difficult to dissolve once it is solidified, so the cleaning agent Voltatex® 5050 cleaning equipment should be used regularly. All settings

The cleaning and maintenance work of prepared needs to follow the instructions of the equipment manufacturer.

Transportation and storage

Voltatex® 4200 provides a packaging method of 20kg and 200kg per barrel. In the unopened original packaging seal container, the storage temperature is not over

After 25 ° C, the resin can be stored for 6 months. The container after opening needs to be sealed immediately to avoid sunlight.

Health and safety

CICS VOLTATEX®

4200 immersion resin has biological inertia and harmless to health. When using liquid resin, specific safety defense

Please refer to the company's Voltatex® 4200 Material Security Data Table (MSDS) and relevant local regulations.

Table 1: Characteristic data of liquid Voltatex® 4200 immersion resin

surface | Yellow-brown, clear or slightly cloudy liquid |

Viscosity (25 °C, per DIN 53019) | 1800 - 2700 mPa · s |

Storage Stability (25 °C) | Six months |

reactivity (100 °C, per to Energy Solutions-Voltatex ® 0141) Gel time reaction time |

representative value

(7.0 13.0) minutes 9.8 (8.0 16.0) min 11.1

|

Curing time: 2) Immersion craft, 130°C Immersion craft, 150°C |

2 Hours 1 Hour |

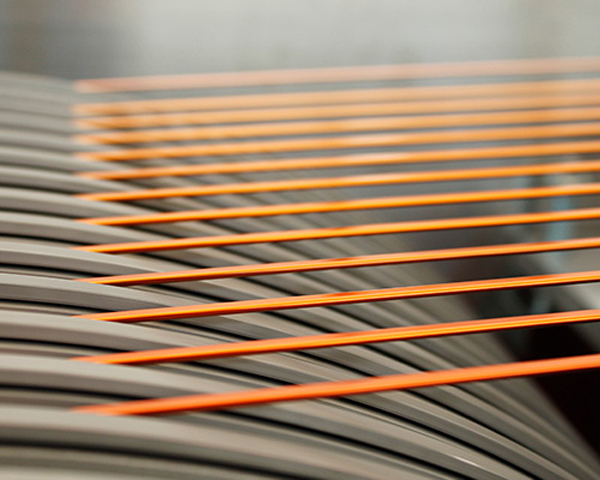

Effect on enameled wire 3) | Compatible with all conventional enameled lines |

VOC content (according to DIN EN 60455-3-5:2006) | About 1.2% (weight ratio) |

The information related to health tips, transportation and labeling for safety handling meets legal requirements as detailed in the Material Safety Data Sheet (MSDS)

(1) Company standard-Voltatex® 014 Test of Gel Time and Reaction Time of Single Group Resin ", according to DIN 46448, the test value is related to the production time, and the reactivity may change with the storage time.

(2) The curing time is calculated from after the temperature of the workpiece reaches the set temperature. For products subjected to high mechanical and chemical stress in operation, a prolonged curing time is recommended.

(3) The test is based on IEC 60851-4:1996 "winding wire test method" part 4: chemical properties, the test solvent can be replaced with the corresponding impregnated resin

Table 2: Characteristic data after curing of Voltatex® 4200 immersion resin (according to IEC-60455-3-5)

Curing conditions of the test samples: 1 hour at 150°C | ||

Twist-twisted coil bond strength (per IEC 60455-2, Test IEC 61033, Method A) room temperature 130°C 155°C 180°C |

(320 ± 40) N (90 ± 20) N (80 ± 10) N (52 ± 12) N | |

Shore D Hardness (Under IEC 60455-2, test method according to ISO 868) room temperature |

77 ± 5 | |

thermal conductivity (Per to ASTM E 1530) 23°C 130°C 155°C 180°C |

(0.21 – 0.23) W (m .K )-1 |

representative value 0.22 0.22 0.22 0.22 |

electrical strength (Per IEC 60455-2, test method per IEC 602431) 23 °C, 50% relative humidity 155 °C 23 °C, 92% relative humidity, 96 hours 105 °C, Transformer oil, 168 hours |

representative value

(70 – 90) kV/mm85(65 – 105) kV/mm80(40 – 90) kV/mm66(85 – 130) kV/mm110

| |

Relative permittivity number ε r (Per IEC 60455-2, Test per IEC 60250) At 23°C, from 50 Hz to 1 MHz |

(4.0 ± 0.5) | |

Dielectric loss angle is tangent to tan δ (Per IEC 60455-2, Test per IEC 60250)

The temperature when the medium loss angle tangent is 0.2 = 200 · 10-3 |

(90 – 150) |

representative value 120°C |

mass resistivity (Per IEC 60455-2, Test per IEC 60093) 155°C 180°C 200°C Diwater for 7 days |

(1010 - 1012) Ω cm (1009 - 1011) Ω cm (1009 - 1011) Ω cm (1014 - 1016) Ω cm |

representative value 2×1011 5×1010 1×1010 3×1015 |

Table 3: Corrosion resistance of Voltatex® 4200 impregnated resin

Resistance to liquid chemicals (Pper Energy Solutions-Voltatex ® 017) | be able to bear or endure -electric insulating oil -distilled water |

Solvent-resistant gas properties (According to the Company standard Energy Solutions Voltatex ® 019) | be able to bear or endure -n-hexane -carbinol -acetone -dimethylbenzene |

Table 4: Thermal properties and heat resistance grade of Voltatex® 4200 impregnated resin

Heat resistance index (Per IEC 60455-3-5, Test per IEC 60216) | 200 |

cohesional strength (According to IEC 61033, Method B, test endpoint standard is bond strength equal to 22 N) | IEC 60317-8/MW 30: 238°C IEC 60317- 13/MW 35:229°C |

Antivoltage breakdown test (Per to IEC 60172) | IEC 60317-8/MW 30: 212°C IEC 6031713/MW 35: 222°C |

Table 5: UL certification of Voltatex® 4200 immersion resin

Temperature resistance grade (Per to UL 1446) Twisted line to method

Spiral coil method |

ASTM D 2307

ASTM D 2519 |

MW 30: 200 MW 35: 220 MW 30: 240 MW 35: 220 |

Electrical insulation system (Per to UL 1446, (IEC 61858)) Level 130

Level 155

Level 180 |

C 190HE R 150HE Z 130HE Z 150HE C 290HE CZ 255HE R 201HE R 203HE Z 200HE R 342HE R 342HE 2 | |