Composite insulation paper(NMN)

Temperature-resistant level: 155 C ° -220C °

Environmental certification: UL, RoHS, Reach, MSDS

System certification: IATF16949

Standard width: 914mm

Packing method: carton

Free sample: A4

Brand: Baigong®

Inquire Now

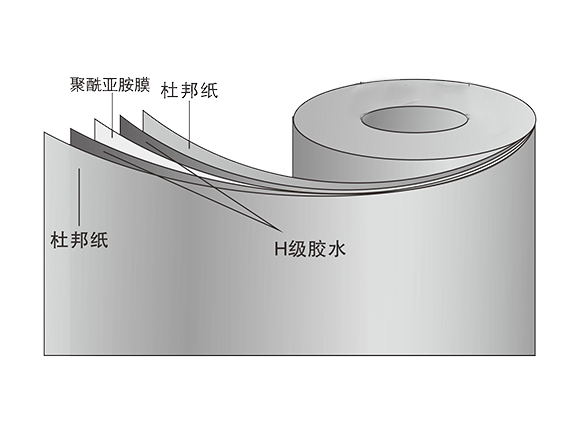

The heat -resistant grade of polyester film polyfordic acid amine fiber paper is F, H levels for the heat -resistant grade of soft composite materials.

It has good electromechanical performance, good cuttings and good loading capacity, and good compatibility with commonly used paint.

Soft, stagnant than 6641 products, easy to cut, cut, play or mold for molding, under normal conditions (20sd5, 50% R.H) can be stored indefinitely.

It is suitable for the slot insulation of the low -voltage motor, the slot cover and the phase insulation, and are also used for inter -layer insulation of the transformer and other electrical appliances.

order number | name of index | unit | desired value | |||||||||||

1 | Outside the present | The surface is smooth, the color is hook, no stains, no wrinkles, no foaming. No impurities | ||||||||||||

2 | Nominal thickness | mm | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | |||||||

3 | The thickness tolerance range | mm | m0.02 | m0.03 | ±0.03 | ±0.03 | m0.03 | |||||||

4 | Nominal quantification and allowable deviation | g/ | 180α15% | 240=15% | 200α15% | 350 ·15% | 430a15% | |||||||

5 |

tensile strength | direction | No wonder 2 | N N / 10mm wide | 150 | 180 | 220 | 270 | 320 | |||||

After 2 | 80 | 130 | 180 | 200 | 250 | |||||||||

broadwise | Do not analyze green 2 | 90 | 130 | 180 | 200 | 250 | ||||||||

After 2 | 70 | 110 | 150 | 170 | 200 | |||||||||

6 | elongation | direction | % | 10 | 10 | 12 | 12 | 12 | ||||||

broadwise | 2 | 15 | 15 | 15 | 18 | 18 | ||||||||

7 | punch through voltage | It's true | KV | 7 | 11 | 13 | 15 | 20 | ||||||

After folding strange | 2 | 6 | 9 | 12 | 13 | 16 | ||||||||

8 | Normal sticky filling | No stratification | ||||||||||||

9 | Sodium state bond 180a2℃ 10min | No layer, can not afford all times, no glue | ||||||||||||

10 | Portable voltage breakdown value With 180x2℃ 10min time temperature test place Perbreakdown experimental values in the blackened environment | |||||||||||||