Voltabas® Immersion paint 0151

Chemical composition: unsaturated polyester, styrene dilution system

Product description: Single component thermosettic impregnation resin

characteristic

• Single component

• High paint efficiency

• Low paint loss

After the solidification, the resin has the following characteristics

• Excellent anti -solvents and heat resistance stress

• High adhesion intensity

• Not easy to crack

Inquire Now

Application

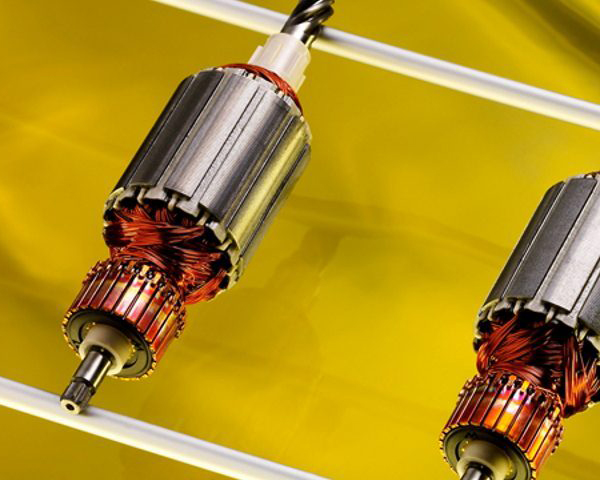

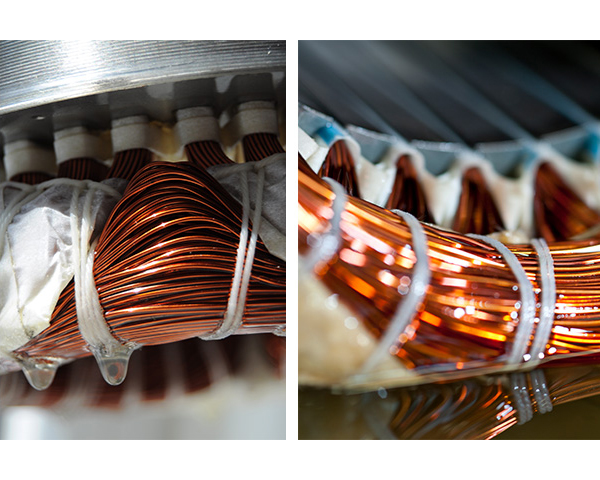

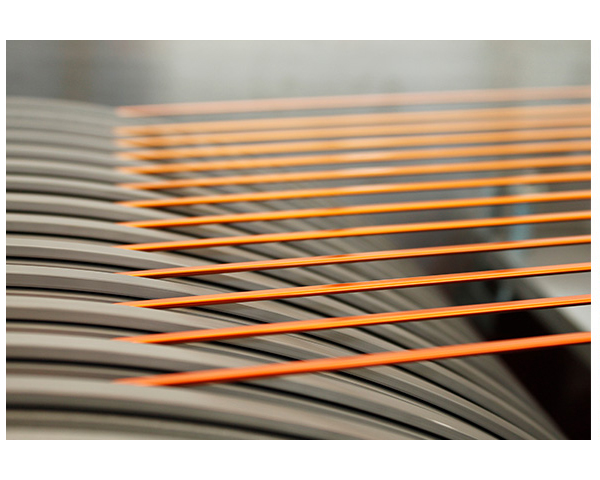

• electric motor

• High -speed motor and high -power motor

• Transformer

mix

Voltabas 0151 can be used without adding another catalyst and curing agent

According to the customer's needs, the viscosity can be adjusted by adding Voltatex® T100 diluents.

Use process

This resin can be used in the following process

• All conventional immersion and decorative process

• Continuous immersion and vacuum impregnation process

• Vacuum pressure impregnation process

Since we cannot list the possible design and application, if we need more suggestions and support, please be with our technical service team.

connect.

Tank maintenance

When the storage is below 25 ° C, if at least 20%of the paint in the monthly paint tank is used and adds a new resin, then you can

Long -term use.

Solidify

In order to reduce the volatilization of the monomer during the curing process, the impregnated workpiece should be heated to the curing temperature in the shortest time. In addition, in

Within the scope of safety permits, the lowest air flow should be maintained during the cured process.

Equipment cleaning

Once the resin is solidified, it is difficult to dissolve, so the Voltatex® T050 cleaning equipment should be used regularly. Clean up all equipment

Maintenance work needs to follow the instructions of the equipment manufacturer.

Transportation and storage

VOLTABAS 0151 provides a packaging method of 20kg or 200kg per barrel. In the unopened original packaging seal container, the storage temperature

When the degree does not exceed 25 ° C, the resin can be stored for 6 months. In order to extend the storage period of the material, the container after opening needs

Seal immediately to prevent sunlight from being illuminated.

Health and safety

The curing Voltabas 0151 immersion resin is biological inertia and harmless to health. When using liquid resin, specific

For security protection measures, please refer to the company's Voltabas 0151 Material Security Data Table (MSDS) and relevant local regulations.

Table 1: Characteristic data of liquid Voltabas 0151 immersion resin | |

surface | Clear, yellow to brown |

Viscosity (25℃, according to DIN 53019) 1) | 200 – 600 mPa ·s |

Storage Stability (25°C) | Six months |

Reactive (100 °C, according to Company standard 0141)) Gel time reaction time |

7 - 18 min 10 - 30 min |

Curing time: 2) | |

130°C | 2 Hours |

150°C | 1 Hour |

Effect on enameled wire 3) | Compatible with all conventional enameled lines |

VOC content (according to DIN EN 60455-3-5:2006) | Less than 10.0% (weight ratio) |