Voltatex® Immersion paint 4012

Chemical composition: unsaturated polyester gale

Product Description:

Yellow -brown transparent liquid, with high permeability of a single -component of thermosettic immersion resin.

Voltatex® 4012 meets the following EU instructions

-2003/11/EU (Polytin Penzide)

-2006/121/EU (Reach instruction)

-2011/65/EU (ROHS instruction)

characteristic

Facilized solidification conditions make the resin use efficiency very high

Low material consumption can achieve excellent impregnation effect while consumption

After curing, resin has the following characteristics:

Excellent solvents steam and heat resistance

Inquire Now

Application

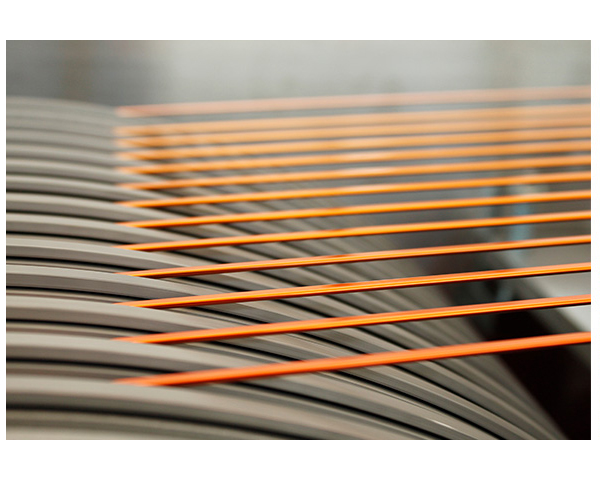

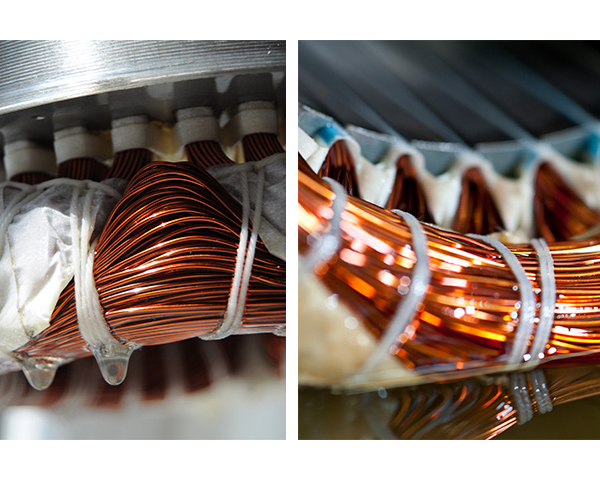

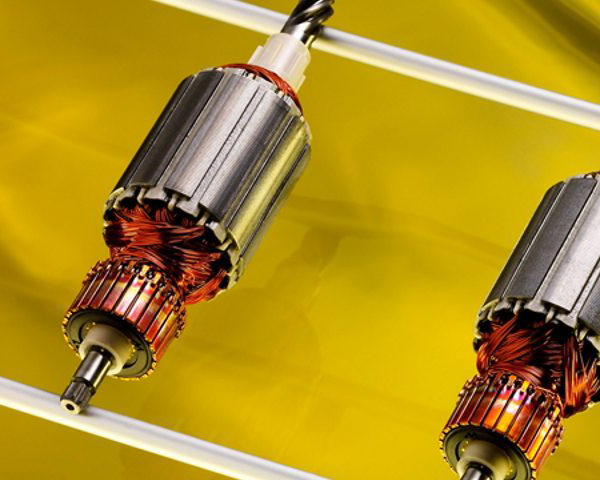

Electric motor (suitable for rotor and stator coil)

A rotor with high mechanical strength and high thermal performance requirements

Suitable for the insulation system for heat -resistant level 200 (N) (according to IEC 60085: 2007)

mix

Voltatex® 4012 can be used without adding other catalysts and curing agents

According to the customer's needs, the viscosity can be adjusted by adding Voltatex® T031 diluents.

Use process

This resin can be used in the following process

Dripping process

Immersion and rolling technology

When Voltatex® 4012 is stored below 25 ° C, at least 20%of the paint in the monthly paint tank is used and adds a new tree

Fast, then you can use it for a long time

Solidify

In order to reduce the volatilization of the monomer during the curing process, the impregnated workpiece should be heated to the curing temperature in the shortest time. In addition, in

Within the scope of safety permission, the air flow should be maintained in the oven during the curing process

Equipment cleaning

Once the resin is solidified, it is difficult to dissolve, so the Voltatex® T050 cleaning equipment should be used regularly. All equipment

The maintenance work needs to follow the instructions of the equipment manufacturer.

Transportation and storage

Voltatex® 4012 provides a packaging method of 20kg per barrel. In the unopened original packaging seal container, the storage temperature is not over

After 25 ° C, the resin can be stored for 6 months. The container after opening needs to be sealed immediately to prevent sunlight from being illuminated.

Health and safety

The curing Voltatex® 4012 immersion resin is biological inertia and harmless to health. When using liquid resin, specific

For security protection measures, please refer to the company's Voltatex® 4012 Material Security Data Table (MSDS) and local relevant regulations.

Table 1: Characteristic data of liquid Voltatex® 4012 immersion resin | |

surface | Brown-yellow clear liquid |

Flow time (23°C per DIN 53211) | 65 ± 7 seconds. |

Viscosity (25℃, according to DIN 53019) 1) | 220 – 260 mPa ·s |

Storage Stability (25°C) | Six months |

Reactive (100 °C, according to Company standard-Voltatex ® 0141)) | |

representative value | |

Gel time reaction time | (5.0 - 7.5) min 6.0 (7.5 – 11.5) min 9.0 |

Curing time: 2) Dipping process, 130°C Dipping process, 150°C |

15 - 30 min 10 - 15 min |

Effect on enameled wire 3) | Compatible with all conventional enameled lines |

VOC content (according to DIN EN 60455-3-5:2006) | About 7.9% (weight ratio) |