Insulation steel paper

Mechanical properties: high mechanical elasticity, high strength, high abrasion resistance

Electrical performance: high -agency strength, high surface resistance, static electrocontrol insulation body

Physical properties: low flammable flammable flash point high in thermal conductivity

Chemical properties: pH neutral, high -resistant environmental protection materials in ordinary organic solvents, and no harmful substances can be degraded naturally

Appearance: flat, clean, no "lotus leaf edge", no wrinkles, no spots, uniform color curly/board materials: according to customer requirements

Automation assembly system: component standardization: size, thickness, shape, flexibility and hardness are suitable for automation processing

Inquire Now

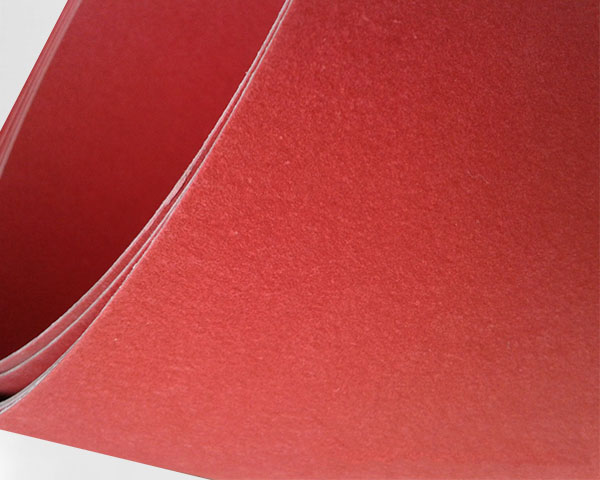

Steel paper is made of cotton pulp and chemical wood pulp, which is made of long nets and copied on the paper machine. The layers are bonded, and then made by aging, rhodolen, salt, and drying and plastic surgery.

Steel paper production

Low moisture

Low moisture absorption, good shape stability, and flattering; the most advanced zinc chloride recovery treatment system to ensure the most pure zinc chloride and cellulose fully react, fibrous intertwined, small steel paper pores, low moisture absorption properties, low moisture absorptionability Essence

Standard certification

Through US security testing UL certification.

Through RoHS Environmental Certification, the product is in line with the EU ROHS instruction

Correction instructions of 2011/65/EU Appendix II (EU) 2015/863 limit requirements.

Through Reach Regulations for certification, the product is in line with the European Union No. 1907/2006

Reach regulations.

Passes national standard certification, the national bid: QB/T2199-1996.

Insulating steel paper index according to the performance requirements of the application field and processing and assembly methods, formulate the general index requirements of insulated steel paper.

specifications (mm) | Thickness requirement (mm) | Widwidth and diameter requirements | Steel paper water | compactness | Interlayer stripping (N/m) | Breakdown voltage (kV / mm) | volume resistivity (Q.cm) | Zinc chloride content | standing cost | remarks | |

September- -the following January | 2-August | ||||||||||

0.5 | 0.49-0.52 | According to customer requirements | 6.5-8.0% | 6.0-7.5% | ^1.10 | &150 | &8.0 | N108 | W0.15% | ||

0.6 | 0.58-0.62 | According to customer requirements | 6.5-8.0% | 6.0-7.5% | ^1.10 | &150 | &8.0 | N108 | W0.15% | ||

0.7 | 0.68-0.72 | According to customer requirements | 6.5-8.0% | 6.0-7.5% | ^1.10 | &150 | &8.0 | N108 | W0.15% | ||

0.8 | 0.78-0.82 | According to customer requirements | 6.5-8.0% | 6.0-7.5% | ^1.10 | &200 | &8.0 | N108 | W0.15% | ||

0.9 | 0.88-0.92 | According to customer requirements | 6.5-8.0% | 6.0-7.5% | ^1.10 | &200 | &8.0 | N108 | W0.15% | ||

1.0 | 0.97-1.03 | According to customer requirements | 6.5-8.5% | 6.0-8.0% | ^1.15 | &200 | &6.0 | N108 | W0.15% | ||

1.2 | 1.17-1.23 | According to customer requirements | 6.5-9.0% | 6.0-8.5% | ^1.15 | &200 | &6.0 | N108 | W0.15% | ||

1.4 | 1.37-1.43 | According to customer requirements | 6.5-9.5% | 6.5-9.0% | ^1.15 | &200 | &6.0 | N108 | W0.15% | ||

1.5 | 1.47-1.53 | According to customer requirements | 6.5-9.5% | 6.5-9.0% | ^1.15 | &200 | &6.0 | N108 | W0.15% | ||

ask: | Steel paper color | ||||||||||

The transverse thickness of steel paper is uniform, the automatic machine requires high material, and the thickness difference is less than 0.03mm | |||||||||||

Tactness uniformity, the banner compactness error is less than 0.03g / cm3 | |||||||||||

, Steel paper smooth, clean, no "flounces", no wrinkles, no spots, uniform color | — | ||||||||||