AVERY tape HPA 1951

Eri Poly Poly Guess Products:

Bubble elastic adhesive;

High resistance temperature and humidity;

Good cohesion and energy absorption performance;

Simple double pet cushion system release.

Avery foam glue product superiority:

The combination of excellent adhesion window lens and framework, low and high surface energy substrates such as PP, ABS and paint steel, glass, computer, etc.

The characteristics of 3D shading;

Stable performance, waterproof resistance, IPX7, IPX8;

Excellent promotion, dripping and rotating resistance provides reliable bonding performance with the lens;

Inquire Now

Avery foam glue product superiority:

The combination of excellent adhesion window lens and framework, low and high surface energy substrates such as PP, ABS and paint steel, glass, computer, etc.

The characteristics of 3D shading;

Stable performance, waterproof resistance, IPX7, IPX8;

Excellent promotion, dripping and rotating resistance provides reliable bonding performance with the lens;

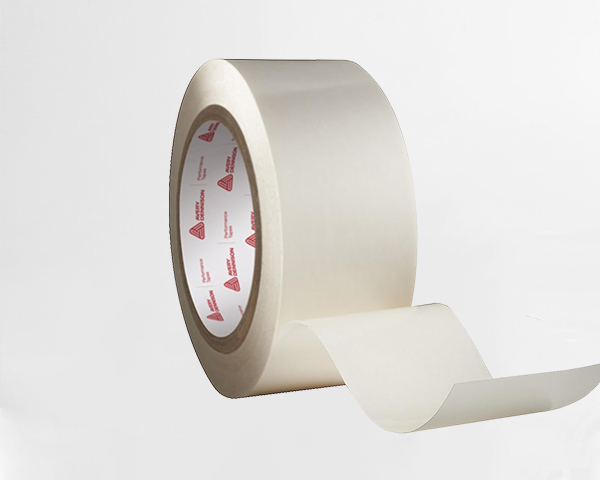

Avery Poly Guess Product Application:

Metal glass bonding;

Control panel accessories;

Installation of sealing;

Mobile phone assembly;

Digital Display.

Adhesive Properties | Typical Values | ||

THICKNESS | US Mils | Typical Values mm | Microns (µm) |

Adhesive | 1.06 | 0.027 | 27 |

Liner | 4.53 | 0.115 | 115 |

Total | 5.59 | 0.142 | 142 |

*PSTC-133

PEEL ADHESION

2 mil PET; 180º; 12" / min,50um Al

Substrate | Lbf / in | N / 25mm | ||

20 min | 72 hr | 20 min | 72 hr | |

Stainless steel | 3.8 | 4.2 | 17 | 19 |

Polypropylene | 1.6 | 2.0 | 7 | 9 |

*PSTC-101, ASTM D-3330, STD-10

LOOP TACK

2 mil PET; 90º; 20" / min; 1" sq (6.5 cm2)

Substrate | Lbf / in | N / 25mm |

Glass | 4.0 | 18 |

*PSTC-16, STD-7

STATIC SHEAR | Min to Fail |

Foil; 1" sq (6.5 cm2); 1000 g | >10,000 min |

*PSTC-107, ASTM D 3654, STD-9

TEMPERATURES

Min | Application | 50 ºF | 10 ºC | |

Max. Continuous Operating Temp. | 400 ºF | 204 ºC | ||

Max. Intermittent Operating Temp. | 450 ºF | 232 ºC | ||

*TEST METHODS

Note: The listed values are typical only and not intended to serve as product specifications

APPLICATION TECHNIQUES

![]() It is essential with all pressure-sensitive tapes the application surface is clean, dry and free of grease and oil

It is essential with all pressure-sensitive tapes the application surface is clean, dry and free of grease and oil ![]() Bond strength is dependent upon the amount of adhesive-to-surface contact developed

Bond strength is dependent upon the amount of adhesive-to-surface contact developed

![]() Note that different pressure, time and temperature on different (firm / rigid) surface achieves different performance

Note that different pressure, time and temperature on different (firm / rigid) surface achieves different performance

STORAGE AND SHELF LIFE

The shelf life of the product is one years when stored at 18-22°C / 64-72°F, 30-70% relative humidity and out of direct sunlight, in original packaging.