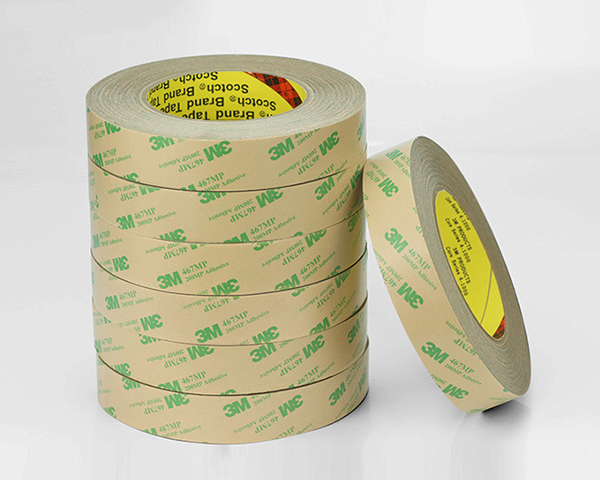

3M tape T467

When adhesion, 3M double -sided glue needs to be operated according to the following ways to obtain an enhanced bonding effect:

1. First clean the surface of the sticky surface must be cleaned. Generally, it is recommended to take 1: 1IPA (opropyl) and the mixture of water and the surface of the water. After the surface is cleaned, the surface is completely dry.

2. After cleaning the solvents, the tape is fitted on the surface of the sticky surface, and the roller or other ways to apply a pressure of about 15PSI (1.05 kg/square centimeters) to effectively bond it.

3. Turn off the tape from the paper, and then stick it to the material, and apply 15PSI pressure to effectively fit it. If the bubbles need to be removed, the pressure should be increased, and the item can bear the limit as the upper limit.

4. The ideal temperature when paste is 15-38 ° C, and do not be lower than 10 ° C.

5. When the tape is bonded, it should be fitted with one end and then pressed to the other end to reduce the chance of bubbles.

The appropriate environmental requirements for 3M double-sided glue storage: the temperature is 19-23 ° C and the humidity is 40-60%.

Inquire Now

3M double -sided glue is widely used in products such as computers, mobile phones, communications, household appliances, audiovisual equipment, automobiles and other products. You can choose according to the application products and environment.

1. Non-woven base materials double-sided adhesion and processability. Generally, temperature resistance is 70-80 ° C for a long time, short-term temperature resistance is 100-120 ° C, and the thickness is generally 0.08-0.15mm. Combine, mobile phone, electrical appliances, seal, rubber, sign, paper, toys and other industries, home appliances and electronic instrument part assembly, display lenses.

2. Without substrate double-sided glue has excellent adhesive effects to prevent falling off and excellent waterproof performance, good processing, good temperature resistance, short-term temperature resistance 204-230 ° C, generally long-term temperature resistance 120-145 ° C. The thickness is generally 0.05-0.13mm, which is suitable for the bonding of the nameboard, panel, and decorative parts.

3. PET substrates have good temperature resistance and strong shear resistance. Generally long-term temperature resistance is 100-125 ° C, short-term temperature resistance is 150-200 ° C, and the thickness is generally 0.048-0.2mm. , Adhesive to decoration and decorative parts.

4. Double-sided glue of foam substrate material has softness, good admission, good initial viscosity, and good stickiness, good anti-solvent properties and good anti-ultraviolet rays, generally 0.4-1.0mm, short-term temperature resistance 130-150 ° C, long-term resistance to long-term resistance The temperature is 80-93 ° C. It is suitable for the bonding of air-conditioners, office furniture, and communication products. It can replace the screw fixed design to make the product more beautiful.

5. The hot melting glue film has good consistency, uniform adhesion thickness, does not contain solvents, is easy to process, has good adhesion to many objects, with a thickness of 0.1mm, translucent/amber color, hot melt, hot melt, hot melt, hot melt Softening temperature is 116-123 ℃. It is suitable for bonding of nameplate, plastic, and hardware; adhesion on the surface of uneven objects can also get good results. It is recommended that the initial bonding conditions are: temperature 132-138 ° C, bonding time for 1-2 seconds, and the pressure is 10 for 10 seconds. -20 pounds/square inch.