Aramid insulation paper A766

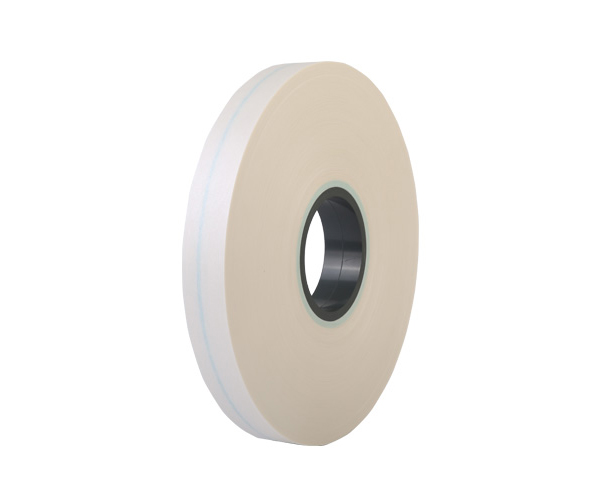

1. The product is a milky white flat paper roll shape. The paper structure is dense and the texture is uniform.

2. The paper surface is flat, smooth, without pores, no hair, no hair, and neat edges.

3. With excellent thermal stability and flame retardability, it can be used normally at high temperatures at 210 ° C for a long time (above H level).

4. High mechanical performance, high stretching strength and tearing strength.

5. It has good compatibility with various types of commercial paint, lubricant, etc.

6. Safe, environmental protection, chemical resistance, and pass certification such as SGS Rohs and Reach.

7. Has excellent electrical insulation performance, high degree of dielectric strength, and low dielectric loss.

Inquire Now

The aramid insulation paper A766 is a high -temperature insulating paper, which is composed of pure aramid fibers. It has excellent high temperature resistance and excellent electrical insulation, mechanical performance and flame retardant. The compatibility of the paint is good, and the H -level and C -level insulation system can be matched at 200. <2 long -term use in the environment.

Aramid insulation paper A766 is suitable for all occasions that need sheet electrical insulation materials, and have strong anti -load capacity. Metallurgical, ships and other motors) and generators' slot insulation, inter -turning insulation and pads insulation.

Aramid Insulation Paper A766

Items | Unit | Typical Value | Test Methods | |||||

Nominal Thickness | mm | 0.05 | 0.08 | 0.13 | 0.18 | 0.25 | GB/T 451.3 | |

mil | 2 | 3 | 5 | 7 | 10 | |||

Unit Quantity | g/m2 | 41 | 63 | 116 | 174 | 249 | GB/T 451.2 | |

Tightness | g/cm3 | 0.70 | 0.79 | 0.87 | 0.95 | 0.96 | GB/T 451.3 | |

D Dielectric Strength n | kV/mm | 17 | 20 | 22 | 24 | 23 | GB/T 1408.1 | |

Volume Resistivity | xiO16Q«cm | 1.8 | 1.9 | 1.8 | 1.8 | 1.8 | GB/T 1409 | |

Dielectric Constant21 | — | 1.5 | 1.6 | 2.3 | 2.5 | 2.8 | ||

Dielectric Loss Factor2) | X103 | 4 | 5 | 6 | 6 | 6 | ||

Tensile Strength | MD | N/cm | 39 | 61 | 128 | 205 | 270 | GB/T 12914 |

CD | 18 | 30 | 62 | 105 | 143 | |||

Elongation | MD | % | 6 | 6.5 | 7 | 9 | 11 | |

CD | 5 | 5 | 5 | 7 | 9 | |||

Tear Resistance | MD | N | 0.5 | 0.7 | 1.8 | 2.5 | 4.2 | GB/T 455 |

CD | 1.0 | 1.5 | 3.0 | 4.8 | 7.0 | |||

Note: The data in the data table is a typical value and cannot be used as technical specifications. Unless otherwise explained, all data was measured under "standard conditions" (temperature of 23 ° C, 50%RH relative humidity).