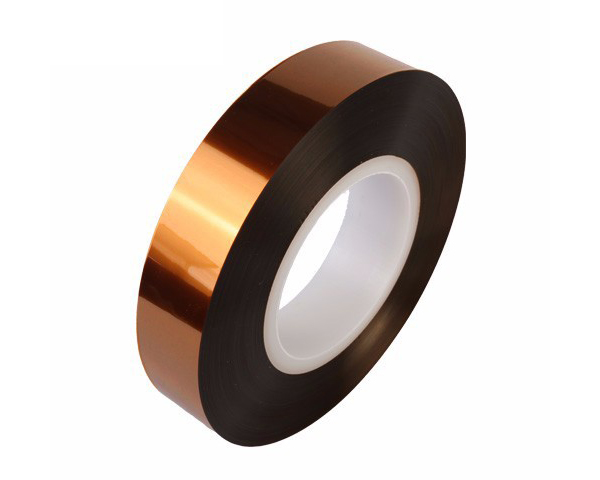

杜邦KAPTON®聚酰亚胺薄膜HN

杜邦Kapton®聚酰亚胺薄膜已成立超过40年的行业标准的高性能,高可靠性和耐用性,以电,热,化学和机械性能能够承受极端温度,振动等苛刻环境的特别组合。Kapton®聚酰亚胺薄膜使创新的设计解决方案可以在一定范围内的行业,包括消费电子,太阳能光伏发电和风力发电,航空航天,汽车和工业应用。

杜邦Kapton®聚酰亚胺薄膜具有特别的电气性能、热性能、化学性能和机械性能的组合平衡性能,并且保留以上各项性能各自的特点,使之广泛应用于工业等领域。杜邦Kapton®聚酰亚胺薄膜不仅在传统工业行业发挥着重要作用,而且在航空航天以及高速机车等行业也提出了创造性的解决方案。

立即咨询

杜邦KAPTON®聚酰亚胺薄膜是由美国杜邦公司开发的一款高性能薄膜类产品,也是目前高性能薄膜类产品的领导者,已经具有超过40年的产品供应、技术支持和客户服务经验。杜邦KAPTON®聚酰亚胺薄膜的市场定位是,要求高性能且能够在极度苛刻环境下稳定使用的高性能要求客户群。

杜邦KAPTON®聚酰亚胺薄膜具有独特的电气性能、热性能、化学性能和机械性能的组合平衡性能,并且保留以上各项性能各自的特点,使之广泛应用于工业等领域。

杜邦KAPTON®聚酰亚胺薄膜不仅在传统工业行业发着着重要作用,而且在航空航天以及高速机车等行业也提出了创造性的解决方案。

基本性能

杜邦KAPTON®聚酰亚胺薄膜作为薄膜领域的专家,具有以下优异特性:

优异的绝缘性能

优异的机械性能

优异的耐热性能、耐寒性能

优异耐化学性能

优异的抗辐射性能

Physical Properties of Kapton® HN at 23°C (73°F)

Property |

Unit | 1 mil 25µm | 2 mil 50µm | 3 mil 75µm | 5 mil 125µm | Test Method |

Ultimate Tensile Strength at 23°C, (73°F) at 200°C (392°F) | psi (MPa) | 33,500(231) 20,000(139) | 33,500(231) 20,000(139) | 33,500(231) 20,000(139) | 33,500(231) 20,000(139) | ASTM D-882-91, Method A* |

Ultimate Elongation at 23°C, (73°F) at 200°C (392°F) | % | 72 83 | 82 83 | 82 83 | 82 83 | ASTM D-882-91, Method A |

Tensile Modulus at 23°C, (73°F) at 200°C (392°F) | psi (GPa) | 370,000 (2.5) 290,000 (2.0) | 370,000 (2.5) 290,000 (2.0) | 370,000 (2.5) 290,000 (2.0) | 370,000 (2.5) 290,000 (2.0) | ASTM D-882-91, Method A |

Density | g/cc | 1.42 | 1.42 | 1.42 | 1.42 | ASTM D- 1505-90 |

MIT Folding Endurance | cycles | 285,000 | 55,000 | 6000 | 5,000 | ASTM D-2176-89 |

Tear Strength-propagating (Elmendorf), N (lbf) | 0.07 (0.02) | 0.21 (0.02) | 0.38 (0.02) | 0.58 (0.02) | ASTM D- 1922-89 | |

Tear Strength, Initial (Graves), N (lbf) | 7.2 (1.6) | 16.3 (1.6) | 26.3 (1.6) | 46.9 (1.6) | ASTM D- 1004-90 | |

Yield Point at 3% at 23°C, (73°F) at 200°C (392°F) | MPa (psi) | 69 (10,000) 41 (6000) | 69 (10,000) 41 (6000) | 69 (10,000) 41 (6000) | 69 (10,000) 41 (6000) | ASTM D-882-91 |

Stress to produce 5% elong . at 23°C, (73°F) at 200°C (392°F) | MPa (psi) | 90 (13,000) 61 (9000) | 90 (13,000) 61 (9000) | 90 (13,000) 61 (9000) | 90 (13,000) 61 (9000) | ASTM D-882-92 |

Impact Strength at 23°C, (73°F) | N •cm•(ft lb) | 78 (0.58) | 78 (0.58) | 78 (0.58) | 78 (0.58) | DuPont Pneumatic Impact Test |

Coefficient of Friction, kinetic (film-to-film) | 0.48 | 0.48 | 0.48 | 0.48 | ASTM D- 1894-90 | |

Coefficient of Friction, static (film-to-film) | 0.63 | 0.63 | 0.63 | 0.63 | ASTM D- 1894-90 | |

Refractive Index (sodium D line) | 1.70 | 1.70 | 1.70 | 1.70 | ASTM D-542-90 | |

Poisson’s Ratio | 0.34 | 0.34 | 0.34 | 0.34 | Avg . three samples, Elon- gated at 5, 7, 10% | |

Low temperature flex life | pass | pass | pass | pass | IPC-TM-650, Method 2.6.18 |

Thermal Properties of Kapton® HN Film

Thermal Property | Typical Value | Test Condition | Test Method |

Melting Point | None | None | ASTM E-794-85 (1989) |

Thermal Coefficient of Linear Expansion | 20 ppm/°C (11 ppm/°F) | - 14 to 38°C (7 to 100°F) | ASTM D-696-91 |

Coefficient of Thermal Conductivity, W/m• K cal cm•sec•°C | 0.12

| 296 K 23°C | ASTM F-433-77 (1987) |

Specific Heat, J/g• K (cal/g•°C) | 1.09 (0.261) | Differential calorimetry | |

Heat Sealability | not heat sealable | ||

Solder Float | pass | IPC-TM-650, method 2.4. 13A | |

Smoke Generation | Dm =<1 | NBS smoke chamber | NFPA-258 |

Shrinkage, % 30 min at 150°C 120 min at 400°C | 0.17 1.25 | IPC-TM-650 Method 2.2.4A; ASTM D-5214-91 | |

Limiting Oxygen Index, % | 37-45 | ASTM D-2863-87 | |

Glass Transition Temperature (Tg) | A second order transition occurs in Kapton® between 360°C(680°F) and 410°C(770°F) and is assumed to be the glass transition temperature. Different measurement tech- niques produce different results within the above temperature range. | ||

Typical Electrical Properties of Kapton® HN Film at 23°C (73°F), 50% RH

Property Film Gage | Typical Value | Test Condition | Test Method | |

Dielectric Strength 25 µm (1 mil) 50 µm (2 mil) 75 µm (3 mil) 125 µm (5 mil) | V/m kV/mm 303 240 205 154 | (V/mil) (7700) (6100) (5200) (3900) | 60 Hz 1/4 in electrodes 500 V/sec rise | ASTM D- 149-91 |

Dielectric Constant 25 µm (1 mil) 50 µm (2 mil) 75 µm (3 mil) 125 µm (5 mil) |

3.4 3.5 3.5 | 1 kHz | ASTM D- 150-92 | |

Dissipation Factor 25 µm (1 mil) 50 µm (2 mil) 75 µm (3 mil) 125 µm (5 mil) | 0.0018 0.0020 0.0020 0.0026 | 1 kHz | ASTM D- 150-92 | |

Volume Resistivity 25 µm (1 mil) 50 µm (2 mil) 75 µm (3 mil) 125 µm (5 mil) | •cm17 1.5 x 1017 1.5 x 1017 1.4 x 1017 1.0 x 10 | ASTM D-257-91 | ||